PET Strapping

PET(-Polyethylenterephthalat)-Strapping in comparison to the PP(-Polypropylen)-Strapping distinguishes itself by clearly higher strength. Further the stretch is lower (higher elongation) and the stiffness is higher- even under hot, humid conditions-, the latter contributes to the fact that PET-strapping, also called Polyester-Strapping or Polyethylenterephthalat-Strapping can be processed more easily, because it can be pushed under a pallet quickly.

personalization

If you are interested in printed PET Strapping we can produce that as well; the minimum purchase here is one pallet in order to compensate the high preproduction costs. This works such that you provide us with the artwork (f.ex. as a pdf file) and we supply you with the proof for your approval. We will then need about 3 weeks for applying the print to your PET strapping.

Characteristics

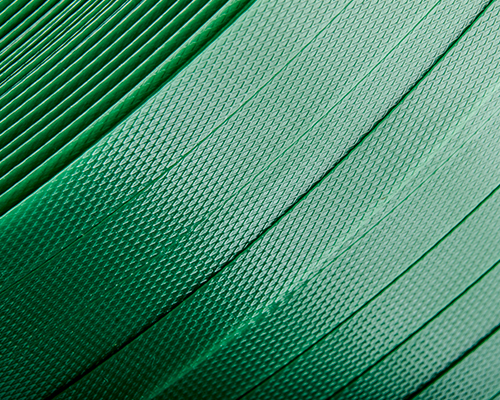

PET-strap comes on a 406 mm core. It is green and available in strapping ranges of 9 – 25 mm. Whereas 9 mm ranges are nearly exclusively used on automated strapping devices, manual and battery-powered strapping devices process ranges of 12-19 mm.

With a 19×1,27 mm PET-Strapping band, for example, a tensile strength of approx. 1,100 kg per cycle can be achieved.

Hence, PET-strap is especially interesting as an alternative to steel strapping. It has the clear advantage that it can be used much more efficiently than for example polyester-yarn-strapping. PET-Strapping does not need to be threaded into metal seals but can easily be tensioned and welded with the help of a battery-powered strapping device.Thanks to a so-called friction-lock, the two ends of the PET-strapping are rubbed and pressed against each other at the same time welding them together that way.

The common dimensions for the use with battery-powered strapping devices are 12,5×0,7 mm, 15,5×0,7 mm, 15,5×0,9 mm and19x1,27 mm PET-Strapping.

Other than band width and thickness we distinguish between smooth and embossed PET-Strapping:Embossed means that the strapping gets an embossment, along which the strength is measured. This is how the nominal band thickness is reached and yet material is saved which allows for a lower price but also results in a lesser tensile strength as compared to the smooth strapping.